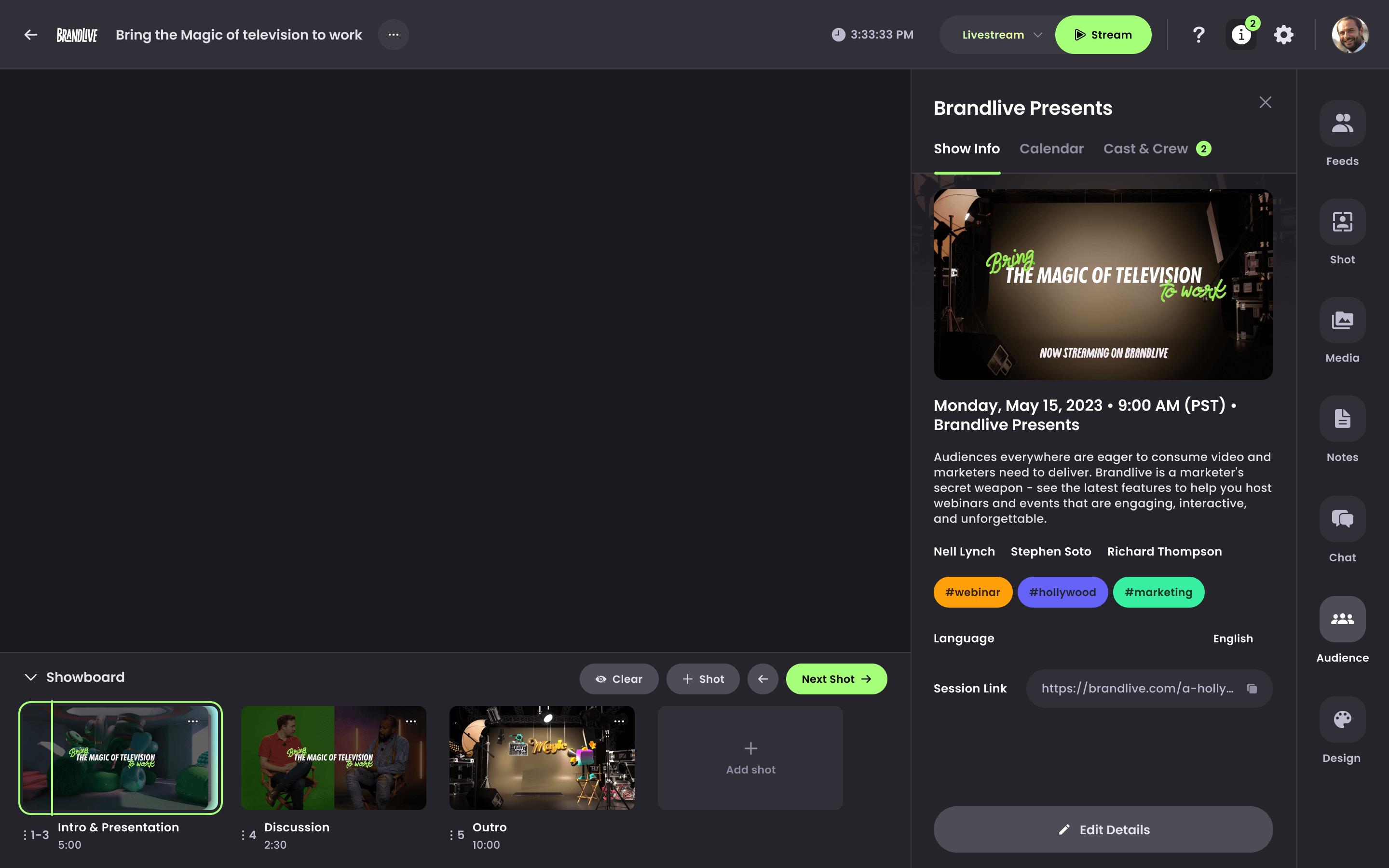

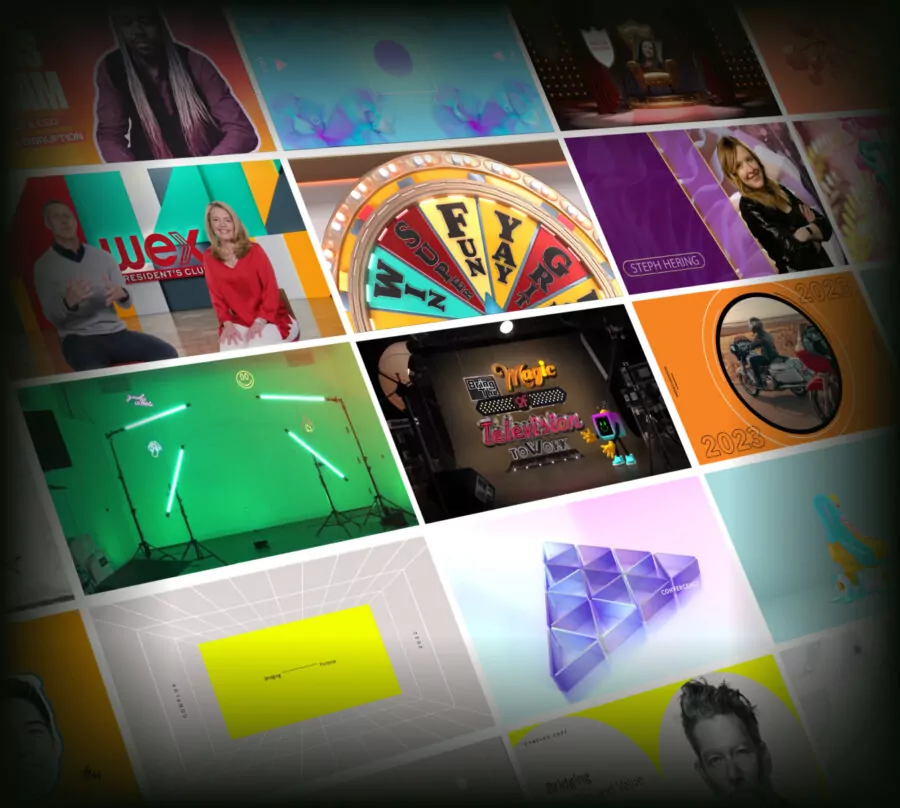

Content that's worth watching

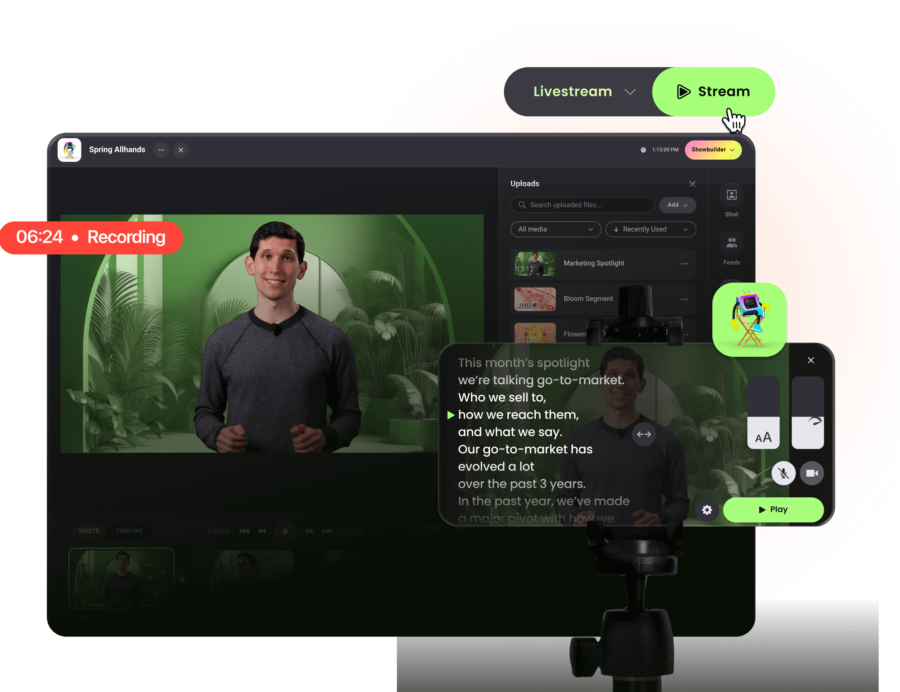

Elevate Every Show

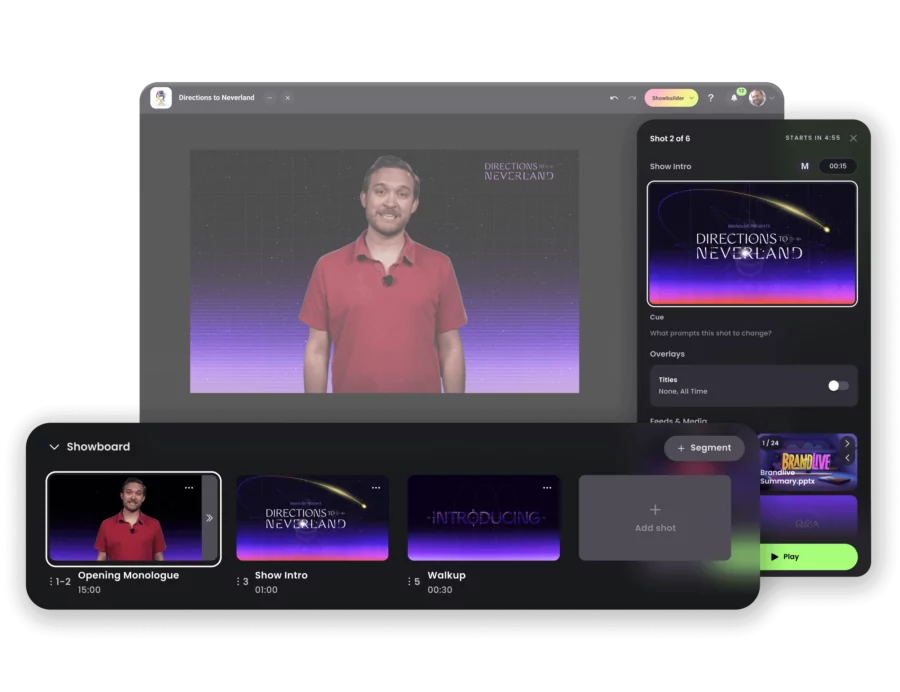

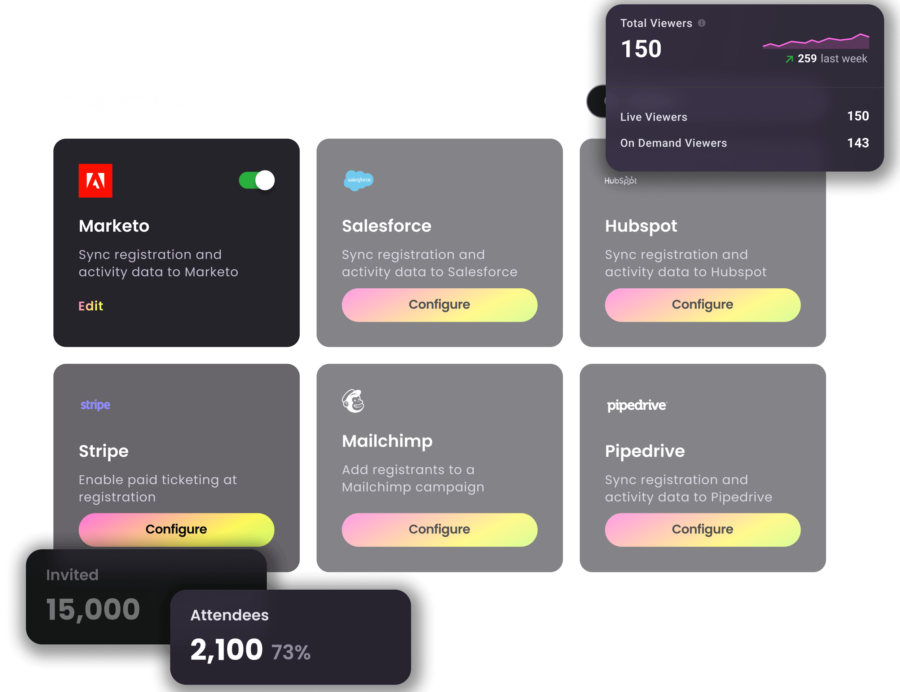

Enterprise focus that scales

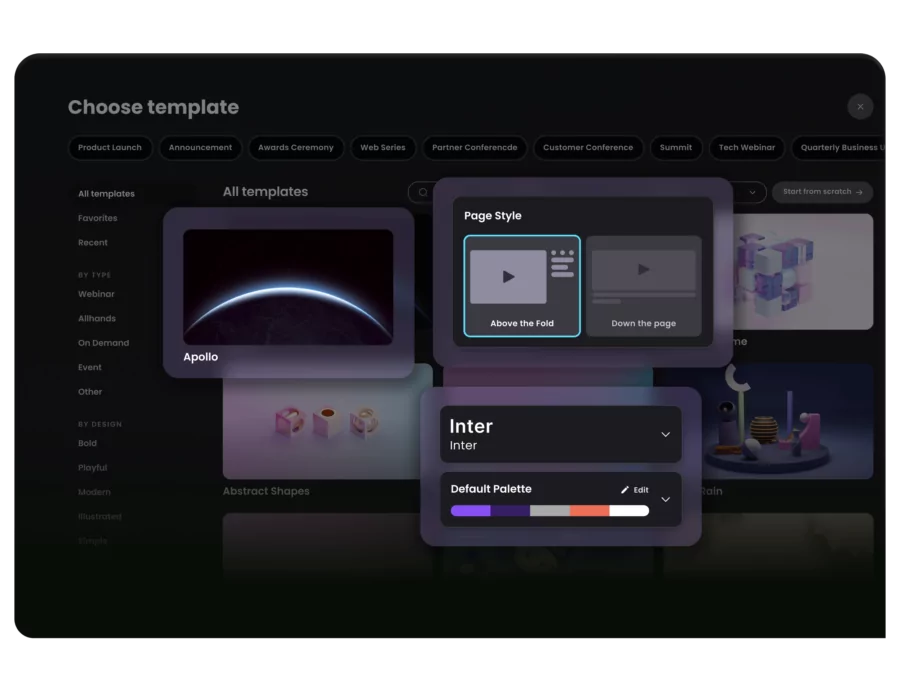

Tools and controls for every team

Partnership mindset that's symbiotic

Give your teams

super powers

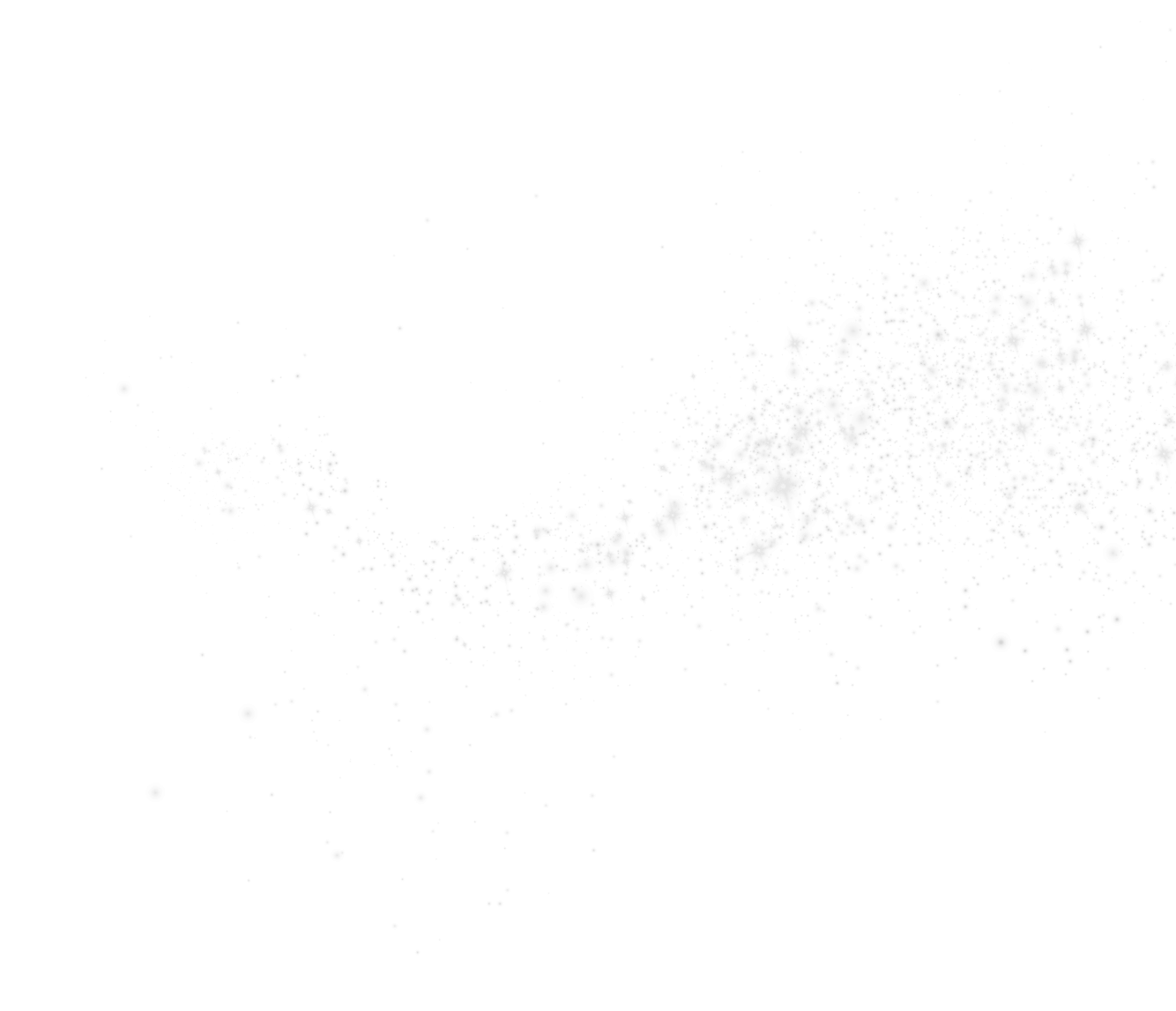

The future of webinars is

now streaming on Brandlive